TEXTILE TABLE PRINTING PROCESS OR HAND PRINTING PROCESS

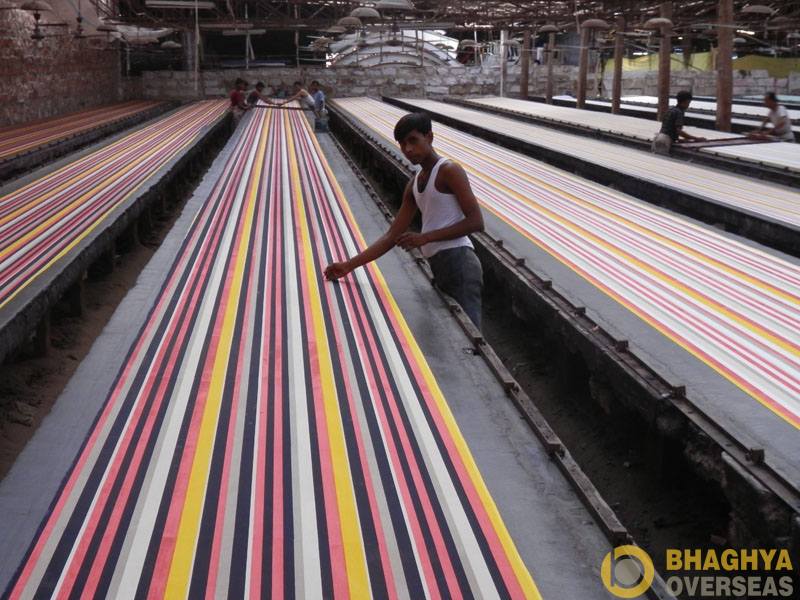

TEXTILE TABLE PRINTING OR HAND PRINTING PROCESS IS A PART OF TEXTILE INDUSTRY. THE MANUAL PROCESS USED TO PRINT A ROLL OF CLOTH WITH THE HELP OF MANPOWER ON THE WAX TABLE IS CALLED IS TEXTILE TABLE PRINTING PROCESS.

TEXTILE TABLE PRINTING IS DONE ON A 45 METER TO 75METER LONG TABLE WHICH IS COATED WITH WAX . THE WAX IS APPLIED ON THAT LONG 45 METER TO 75 METER TABLE. THE PURPOSE OF APPLYING WAX ON THAT IS TO HOLD THAT CLOTH WHICH IS TO BE PRINTED. WAX ACT AS A GLUE FOR THAT CLOTH SO THAT THE CLOTH REMAIN STRETCHED ON THAT TABLE AND THE PRINITING PROCESS CAN BE DONE EASILY AND ACCURATELY ON THAT.

TEXTILE HAND PRINTING INVOLVES A CAREFUL EXAMINATION OF WHAT IS TO BE DONE ON A ROLL OF CLOTH AND WHEN IT IS TO BE DONE. HAND PRINTING PROCESS IS VERY MUCH DEPENDENT ON THE CLIMATIC AND WEATHER CONDITION. THIS IS SO BECAUSE IT IS MOSTLY DONE UNDER THE UNFINISHED OR RAW ROOF, BECAUSE IT REQUIRES SUNLIGHT TO ABSORB COLOUR AND MAKE IT DRY WITHIN A TIME INTERVAL.

THE TOTAL PRODUCTION CAPACITY OF HAND PRINTING PROCESS RANGES FROM 1500 METERS TO 3000 METERS PER DAY. THE REASON OF LOW PRODUCTION CAPACITY IS DUE TO THE INVOLVEMENT OF HAND PROCESS. AS IT IS TOTALLY A LABOUR ORIENTED WORK.

THE TABLE PRINTING OR HAND PRINTING PROCESS INCLUDES THE FOLLOWING

- THE DESIGN TO BE PRINTED : THE VERY FIRST PROCESS INCLUDES THE DESIGN TO BE PRINTED ON THE ROLL OF CLOTH, WHICH MEANS THE TOTAL NUMBER OF COLOUR TO BE USED IN THAT PARTICULAR DESIGN. WHETHER THE DESIGN IS OF PRINTED SCARVES, LADIES SCRAF, PRINTED PAREO, ETC.

- METAL FRAME OR SCREEN: THE VERY NEXT STEP IS THE DEVELOPMENT OF THE SCREEN. THE SCREEN IS MADE OF METAL FRAM WITH A THIN LAYERED FABRIC IN THE CENTER ON WHICH THE DESIGN IS MADE. THE DEVELOPMENT OF THE SCREEN DEPENDS ON THE NUMBER OF COLOUR IN THE DESIGN. FOR EXAMPLE IF THE TOTAL NUMBER OF COLOUR IS 5 IN A PARTICULAR DESIGN THEN A SEPARATE SCREEN IS MADE FOR AN INDIVIDUAL COLOUR SO 5 SCREENS ARE MADE FOR A 5 DESIGN COLOUR.

- FABRIC TO BE USED: THE FABRIC TO BE USED. THERE ARE PLENTY OF FABRIC IN THE FIELD OF TEXTILE. IT MAY BE COTTON PRINTED, VISCOSE PRINTED, CAMRIC PRINTED, TWILL PRINTED, CHIFFON PRINTED, GEORGETTE PRINTED, SATON, VOIL, ETC. THE FABRIC DECISION IS MADE BY THE BUYER AND HE ONLY DECIDES WHICH FABRIC HE OR SHE WANTS FOR THIS PARTICULAR PRODUCTION.

- COLOUR AND CHEMICAL: THE COLOUR AND CHEMICAL PLAYS AN IMPORTANT ROLE IN THE PRODUCTION PROCESS. THIS PROCESS NEEDS A VERY CAREFUL AND DETAILED EXAMINATION OF THE CHEMICAL TO BE USED. AS A POINT MISTAKE CAN CHANGE THE OVERALL PRESENTATION. THERE IS A SEPARATE STAFF FOR THIS PROCESS WHO KEEP ON WORKING TO PROVIDE A EXACT AND ACCURATE LEVEL OF THE PRINTING DESIGN.

- SILICATE PROCESS: THE NEXT STEP IS OF SILICATE PROCESSING. THIS PROCESS IS DONE TO MAKE THE PRINTED CLOTH COLOUR FASTNESS. WHICH MEANS AFTER PASSING THROUGH THIS SILICATE PROCESS THE COLOUR OF THE CLOTH GETS FASTENED AND WHICH REMAINS INTACT AFTER USE. THIS PROCESS MAKES THE COLOUR OF THE CLOTH PERMANENT.

- WASHING AND DRYING: AFTER SILICATE PROCESS THE CLOTH IS KEPT IN A TANK OF WATER FOR MORE THAT 6 TO 12 HOURS AND AFTER THAT THE CLOTH IS WASHED SO THAT THE SILICATE LAYER WAHSES OFF AND THE COLOUR GETS BRIGHTENED. AFTER WAHSING THE CLOTH IS THEN DRYED WITH THE HELP OF MACHINE OR IN THE SUNLIGHT.

- FINISHING : AFTER THE STEP NO. 6 THE CLOTH IS SENT IN THE FELT UNIT. FELT UNIT IS ONE WHERE THE CLOTH GETS FINISHED AND THE WRINKLES GETS OFF THE FABRIC. THE FELT PROCESS IS MACHINERY ORIENTED. THE RANGE OF FELT MACHINE IS DIVIDED INTO SEGMENTS LIKE ZERO FELT, GOTTA FELT, ETC. THESE SEGEMENTS ARE USED ACCORDING TO THE BUYER DEMAND.

- METERAGE : THE NEXT PROCESS IS OF METERAGE THAT IS MEASURING. THIS PROCESS INVOLVES THE MEASUREMENT OF THE CLOTH IN TERMS OF METER UNIT. THIS IS DONE MANUALLY.

- PACKING & DISPATCH : THE LAST AND FINAL PROCESS IS OF PACKING. PACKING IS NORMALLY DONE IN POLY BAG AND THEN IN A CARTON AS A MASTER PACKING. THE PACKED GOODS ARE THEN DISPATCHED AT THEIR PARTICULAR DESTINATION.